Using Sustainable Materials

In our ongoing commitment to operating sustainably, we are on a journey to incorporate more eco-friendly materials in our production. This transformative journey is a result of collaborative initiatives across all our teams contributing innovative solutions and adopting sustainable practices.

We highlight some key changes and advancements we’ve made across teams around the Press.

Oxford Revise

We launched a new revision series with a bold, exciting new brand—Oxford Revise—designed for learners preparing for Key Stage 3, GCSE, and A-Level in the UK. This is driven by our belief that all students should be able to revise effectively and sit exams with confidence. We are determined to make revision fairer.

We know that students demand that the resources they use protect the planet, and we agree. Whilst there is still much to do, we are always looking to improve and are confident that we are taking the right steps towards sustainable revision.

A survey by Natural England revealed that nearly 8 in 10 8–15 year-olds (78%) agreed that looking after the environment was important to them, and more than 8 in 10 (81%) said they wanted to do more to look after the environment.

Oxford Revise is printed in the UK, on Forest Stewardship Council certified sustainable paper, and using vegetable-based inks. The series is produced at our headquarters office in Oxford, which sources zero-carbon electricity and sends zero waste to landfill.

Read more about our sustainability promise.

Sustainable Marketing Working Group

The OUP Sustainable Marketing Working Group was created in 2022 with representatives from all OUP divisions.

One of the group’s first projects was drafting a Sustainable Marketing Toolkit, with guidance about more sustainable choices for the following marketing areas: Using print collateral, Marketing merchandise, Gratis—print and digital, Events—in person, remote, and hybrid, and Avoiding greenwashing.

The toolkit also contains information about OUP’s Commitment to Sustainability, OUP and the UN Development Goals and approved messaging, OUP Sustainable Marketing Charter, Case studies, and next steps on how to get involved.

The toolkit has been made available to colleagues in marketing teams OUP-wide, and feedback about it has been collected. While feedback has been very positive, indicating an appetite for a switch to more sustainable activities, some of the barriers mentioned were:

- Markets can vary in their access to digital resources, and many places are not ready for a switch to receiving information only in digital form

- Expectations from markets and sales teams also vary, with printed catalogues still the norm in some regions.

Marketing initiatives shaping the future of sustainability at OUP

These are some of the initiatives already in place with different marketing and marketing support teams in OUP:

The Marketing Shared Services and Operations (MSS&O) have selected alternatives to produce print materials and exhibition display items for the Academic Marketing Tower teams:

- All paper products are produced using FSC-certified paper for large format displays (such as show cards, floor–standing, and hanging banners), fully recyclable materials are used for all UK produced products, and for nearly all but one of USA produced products.

- In-person event attendance has reduced, cutting transport emissions, and the quantity of printed display books and journals has also been reduced.

The Sustainability in Library Conferences Working Group has also developed digital resources to:

- Move away from unsustainable conference giveaways

- Move towards interactions and sustainable content – including games and downloadables, with only limited print materials at the stand

- Capture leads and cultivate potential customers.

By reformulating their catalogue, the International Education Marketing team has managed to:

- Reduce in print by 80,000 catalogues (nearly 4 million pages)

- Reduce in carbon emissions by not shipping to over 180 countries

- Increase in landing page views by 35%

- Increase in Catalogue engagement

- Views increased by 18%

- Page views increased by 20%

- Link clicks increased by 167%

- Average reading time increased by 12%.

Design and Media team

Our Director of Sustainability brought together manufacturing teams and the Design and Media teams to change various finishes on our children’s books to more sustainable materials.

Designers across the team attended a briefing and training session to raise awareness of non-sustainable materials used in cover and book production. From this, we managed to compile a checklist of dos and don’ts.

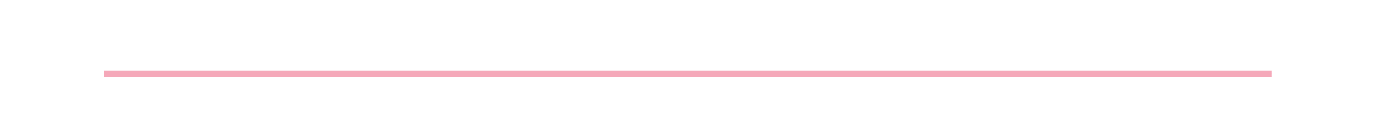

We identified the top-selling children’s fiction series—Isadora Moon, Mirabelle and Emerald and we replaced the Glitter on the covers with a reduced amount of Foil.

We have also modified our designs across the children’s list, so that we are using less foil on our covers in general, most of our latest titles have spot UV and Embossed finishes.

While it was a challenge for the designers to produce standout designs without special non-sustainable finishes, they all agree they can still achieve design excellence without them.

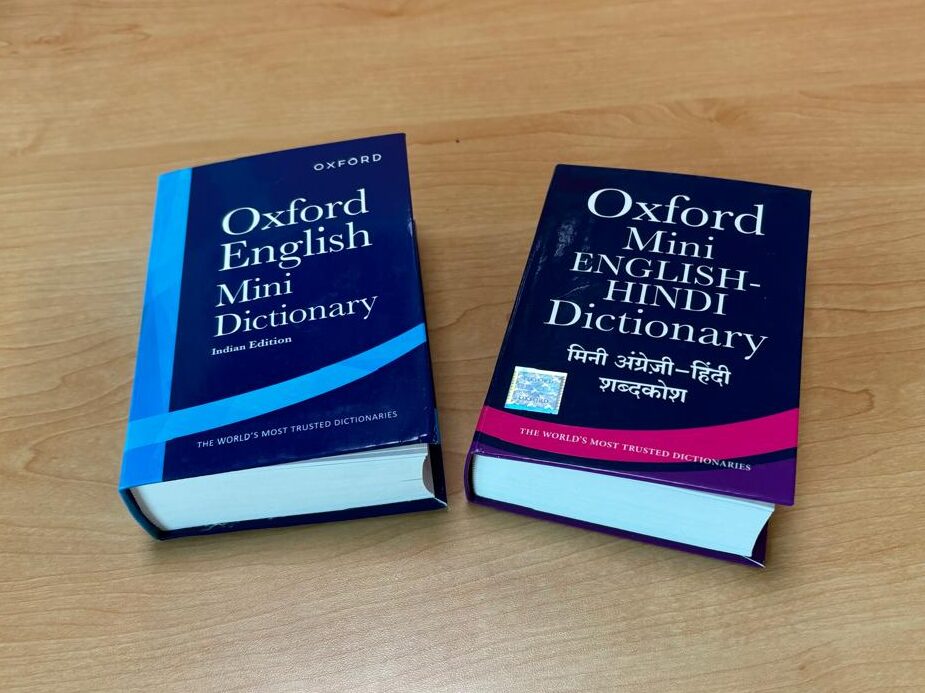

Oxford Mini Dictionary cover

Our Mini Dictionary is one of the highest selling products in the dictionary segment of OUP India. Previously, it had a PVC jacket, creating manufacturing challenges—both in sourcing the PVC material and in achieving high print quality.

Our manufacturing team explored different sustainable materials to improve the overall product quality.

With previous editions, the printing of PVC jackets was done through a screen-printing process. The jacket design had its limitations because the printing substrate was PVC material. The new flexi-bound cover is printed through an offset printing process and the substrate used is card-cover.

Different stakeholders appreciated the change because the flexi-bound cover material is more sustainable and it reduces the manufacturing challenges and print quality of the product. Making this move from PVC to card cover eliminates 15 to 20 metric tonnes of plastics annually.